Multitasking Machining Centers with Built-in Automation

About Famar

Since 1973, FAMAR has provided manufacturers with innovative CNC machining solutions for high-volume machining of complex parts. All FAMAR multitasking machining centers are designed with inverted spindles making automation a standard feature allowing manufacturers to perform turning, milling, grinding, hobing, skiving and other operations completely unattended.

At IMTS 2024 in Chicago, see a FAMAR Tandem 260 multitasking turning center with twin-spindles, twin-turrets and built-in automation for high-volume machining of precision parts for engines, transmissions and more. Look for the FAMAR Tandem in Select's booth along the Front Row of the Metal Cutting Pavilion in booth #339100

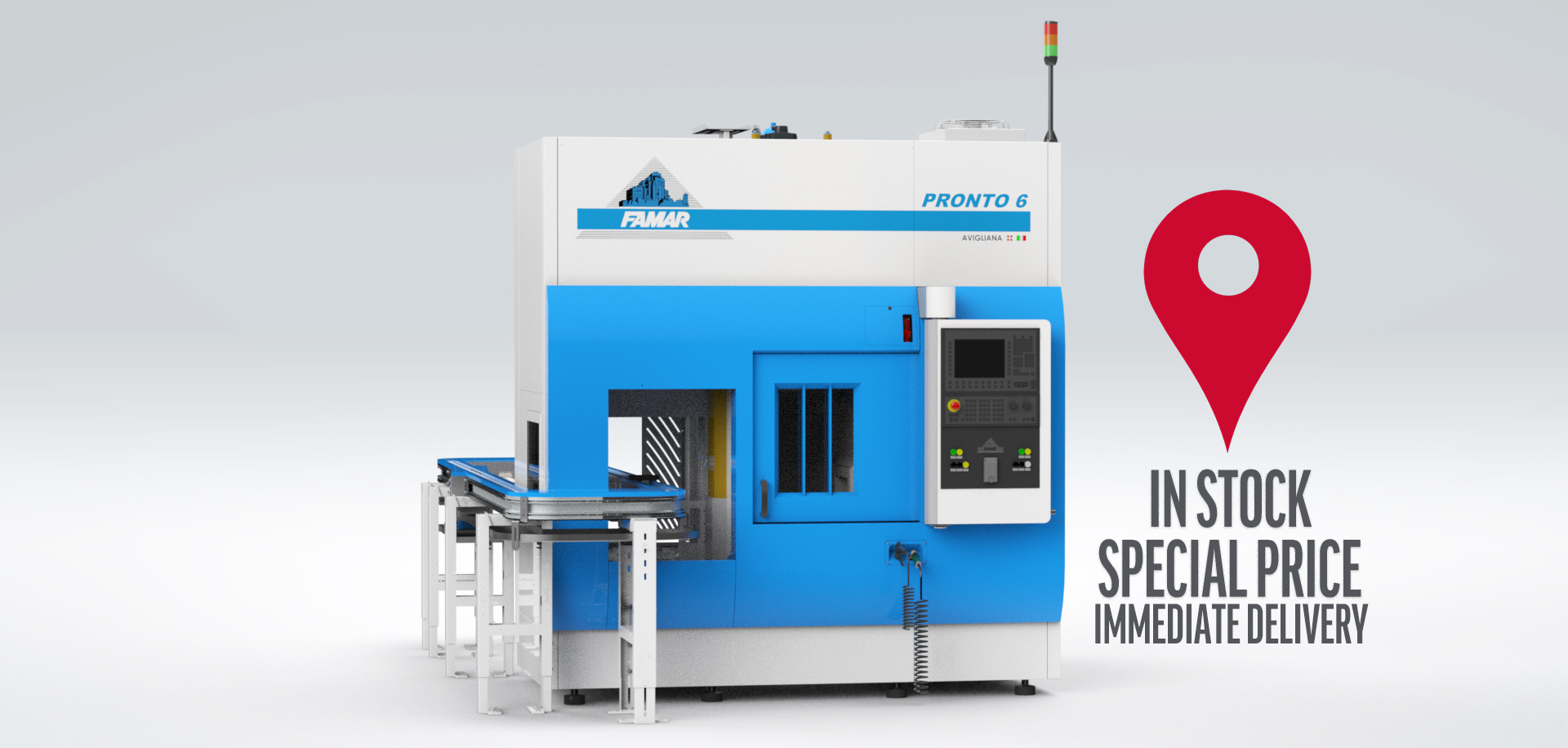

FAMAR PRONTO 6 - In Stock and Ready to Ship

We currently have a well-equipped Famar Pronto 6 inverted spindle turning center in stock and ready for immediate delivery at a special price. The multitasking machine is features a 6” chuck, pallet loading and unloading conveyor, 12-position live tool turret, "X" axis linear scales and standard chip conveyor.

ERGO

Multiprocess CNC Machining Centers

FAMAR ERGO range offers stand-alone or production line solutions for all types of machining operations, from turning and drilling to milling, hobbling and grinding in one machine

TANDEM

High-Volume Machining Solutions

The Tandem range maximizes productivity while minimizing footprint. Two independent pallet conveyors feed the work area and loading system, enabling output to be doubled

PRONTO

Vertical Turning Solutions

Vertical turning lathes ideal for both small and big batches and for all types of machining operations, Pronto strikes the right balance between flexibility and costs savings

SUB

Automated Machining Solutions

FAMAR's Sub line is integrated with automation technology that loads and unloads parts in three seconds flat. The Sub model features two work areas, enabling output to be doubled or the one workpiece to be machined in two phases.

MAXER

Integrated Production Solutions

The Maxer range replaces the traditional use of a “lathe + machining center + gantry loader,” thus reducing investment costs and saving on space. Pieces can be machined in a single set-up, minimizing geometric and shape defects

SPECIAL

Special Machining Solutions

Famar engineers custom-engineered solutions built upon existing FAMAR models, which are tailored to customer-specific production applications, with a view to satisfying customers’ needs in full

Experienced Distribution Local To You

Select Production Technologies represents globally recognized brands of CNC machine tools designed and engineered for high-volume production of complex parts. We support and distribute this technology through experienced industry-leading distribution companies which include; Robert E. Morris Company, Morris Great Lakes, Morris Midwest, Morris South, and Technical Equipment Sales. By combining high-performance technology with the industry's most knowledgeable distribution channel, we deliver the optimal solution for your high-volume production challenges.

FAMAR ERGO 260G

Andrea Marchioro provides a brief walkaround presentation of the ERGO 260G multitasking turning center set up to precision machine transmission gears. The ERGO 260G features an ID grinding spindle and 8-station turret along with a built-in pallet conveyor feeding gears into the main spindle to load and unload