IMTS FRONT ROW

SELECT is excited to return to IMTS, this time along the prestigious FRONT ROW of the South Building, in booth #339100.

With more than double the exhibit space, we plan to exhibit some of the BIGGEST machines at this show, making this a must see booth. Here you'll see advanced manufacturing technology from our partners SORALUCE, GEMINIS, IBARMIA, and MOMENTUM.

Our sister company, Select Production Technologies will also be exhibiting advanced technology from partners FAMAR and FAUSTO MARINELLO. And finally, Select Additive Technologies will have a STRATASYS 3D Printer powered up and making sample parts.

FAMAR TANDEM 260

See the Famar Tandem 260, twin inverted-vertical spindle multitasking turning centers with automation already built in. Because the spindle is inverted, it's also able to load and unload parts as they are passed from one spindle to the other to perform multiple machining operations completely unattended.

Famar turning centers are designed to be seamlessly integrated into a full production cell, making them the ideal solutions for high-volume production applications.

- 13.78" Max Swing, 10.25" Max Turning Dia.

- 9.45" Max turning length

- A2-6 Spindle Nose

- 41.6 HP, 5,300 RPM

- 12 (x2) Position Live Tool Turrets (CAPTO/HSK), 16.7 HP, 10,000 RPM

- Coolant System & Chip Conveyor

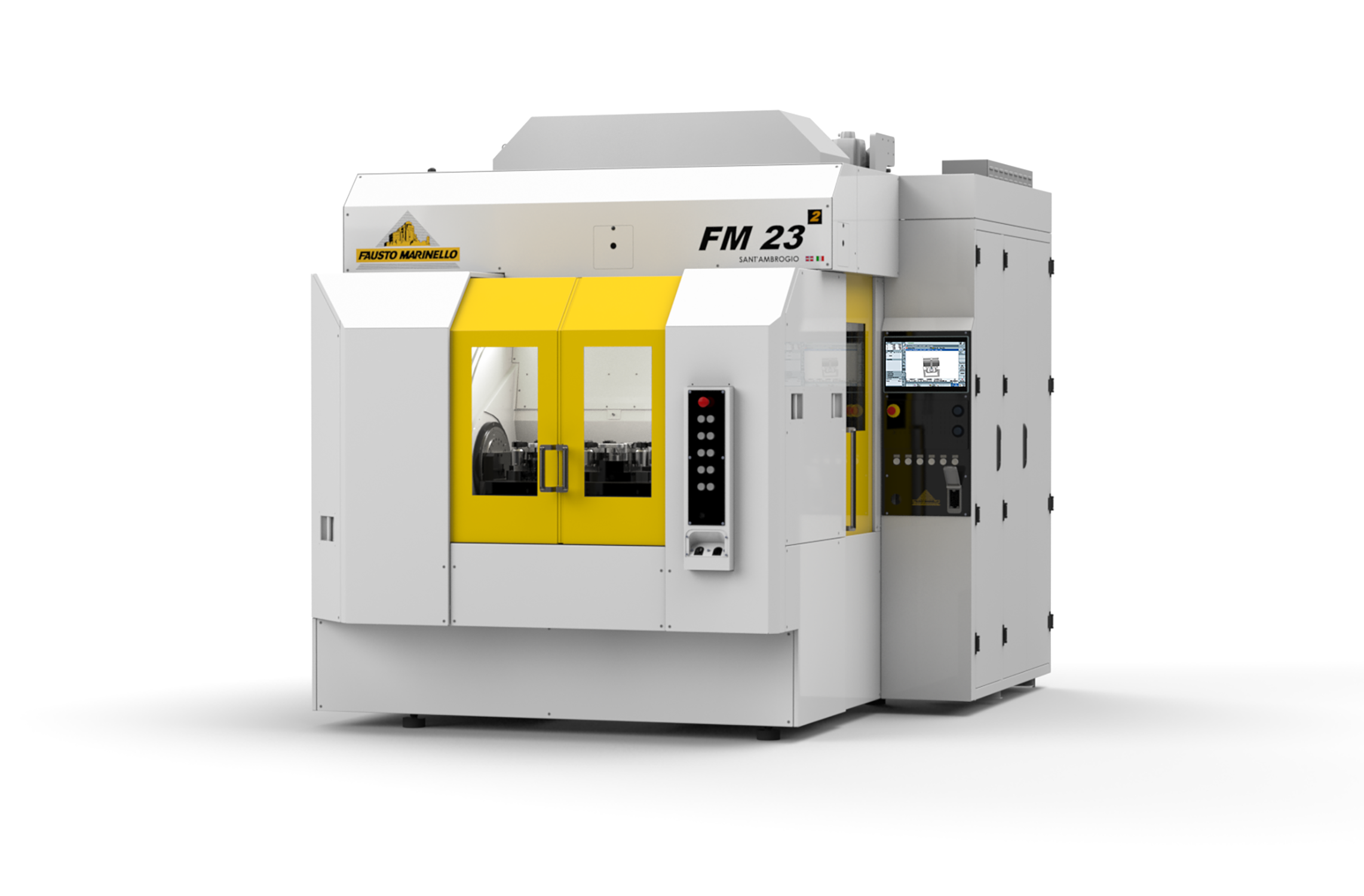

FAUSTO MARINELLO FM23

See a Fausto Marinello FM23 twin-spindle 5-axis horizontal machining center performing live-cutting demonstrations on two completely different parts simultaneously with its fully independent spindles.

This innovative machining center offers a compact footprint and is engineered for high-volume production applications on highly complex parts.

- 13" / 19.7" / 15.75" Travels (X,Y,Z)

- 12.59" Distance Between Spindles

- Full 4th and 5th Axes

- 65.7 HP, 14,000 RPM, HSK 63

- 28 (x2) Position Automatic Tool Changer

- Premium Coolant and Chip Conveyor Systems